Memory is an essential component in every computer, no matter the size and application. All edge devices must, therefore, be ready to tackle any thermal and physical hardship posed by the environment. This is ever more crucial as we keep moving and more computing power to the edge to decrease latency and create more efficient systems. What this means is that devices previously located in a centralized and stable location are now placed where the actual data is gathered. These locations can be anything from a factory floor, a busy road intersection or onboard a ship or an airplane. One of the main challenges that tie these applications together is wide temperature variations. While temperature variations can be part of natural cycles, climate change is another factor that can affect future and already existing systems, as it in many places can lead to more unstable weather and unforeseeable changes.

This paper will explain the background of DRAM wide temperature specifications, as well as its application and testing procedures.

Background:

The specification 'industrial-grade wide temperature' is usually defined by the temperature range −40°C to 85°C. For Innodisk, these numbers are based on JEDEC specifications that are further expanded on to suit industry requirements. JEDEC is an organization that develops open standards for the microelectronics industries. The standards are created through tight-knit cooperation between manufacturers and suppliers and are employed on a worldwide basis. For standard temperature DRAM, the applicable standard is 21C. For wide temperature, there are separate standards that outline specifications for different DRAM types. The standards describe in detail both manufacturing requirements and testing of wide temperature DRAM modules.

Challenges:

The trends of IoT and edge computing both contribute to more devices and computational power being placed in harsher environments. These include both places with extreme heat and cold, as well as areas susceptible to the adverse consequences of climate change.

For example, a device placed outside will run through a continuous cycle of heating and cooling with the change from day to night, and on a longer cycle with seasonal changes. These locations can also be hard to access which increases the time and cost of maintenance.

It is imperative that devices that run in these areas utilize memory modules that can handle these circumstances over long periods with minimal attendance.

Solutions:

The JEDEC Standard specifies the temperature range for the whole DRAM module and DRAM integrated circuits (IC) respectively. Innodisk follows this guideline which also states that maximum TC shall not exceed the value specified for the DRAM component. The temperature range for DRAM modules is designated as TA, which refers to the ambient temperature. JEDEC puts this range at:

0°C ≤ TA ≤ 55°C

The case temperature (TC), which refers to the temperature of the IC during operations, will naturally be higher as it is at least the same as the ambient temperature with heat produced during operations added on top. I.e., TC is equal to TA plus heat produced. JEDEC sets this range to:

0°C ≤ TC ≤ 85°C

The Innodisk standard for wide temperature modules is built on the JEDEC standard and is further extended into the negative range:

-40°C ≤ TA ≤ 85°C

This range allows modules to operate in environments that significantly surpass the JEDEC standard, both for ambient and IC temperature (as TC is always the same or higher than TA).

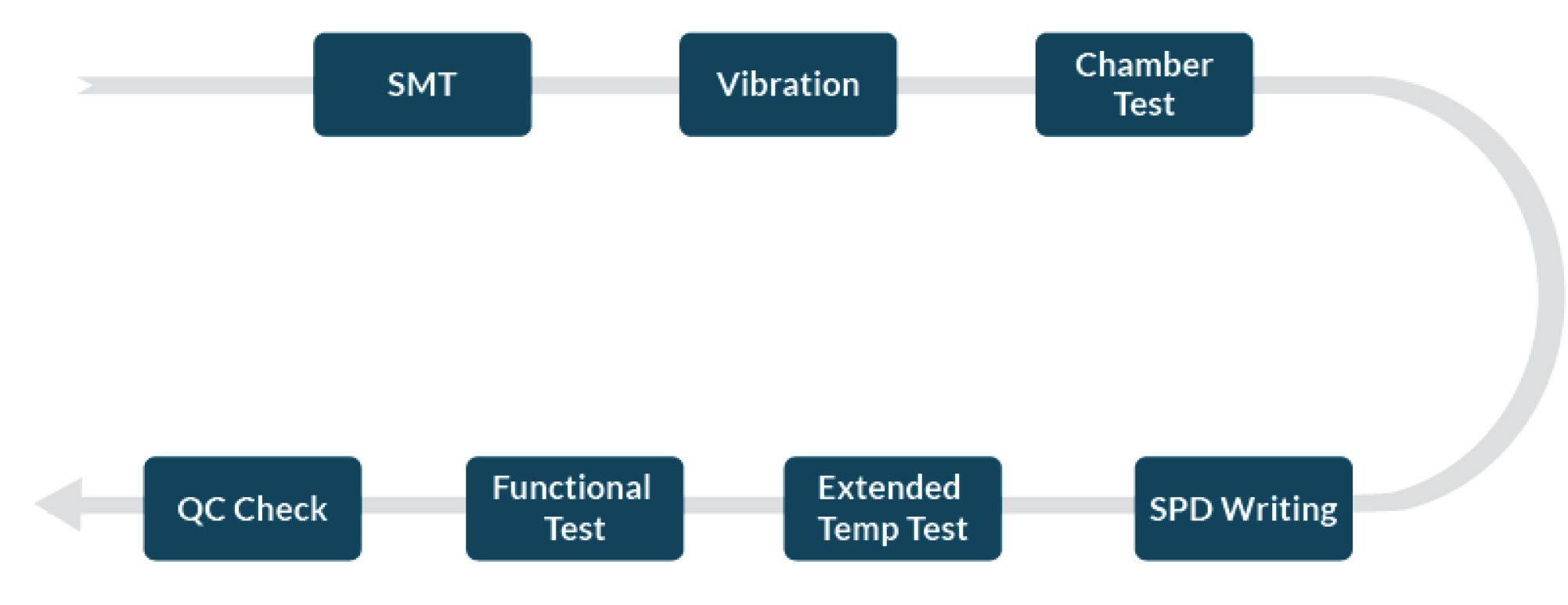

Testing and Quality Control: To verify wide temperature capability, as well as robustness and product quality, the modules will run through a standardized testing process as seen below.

Once having cleared this process, the modules are verified for use in wide temperature environments.

Conclusions:

Wide temperature specifications are crucial in ensuring that your device survives the extreme conditions seen in the surveillance, in-vehicle, factory, networking, and mission-critical markets. The need for wide temperature memory is set to increase as computational power moves out into the field where robust IoT devices are essential for longevity and efficient maintenance.

Wide temperature plays a part in the wider set of tools that ready memory for harsh environments. Combining it with anti-sulfuration, coating, side fill, and heat spreader allows the operator to tailor a solution specific to their application.